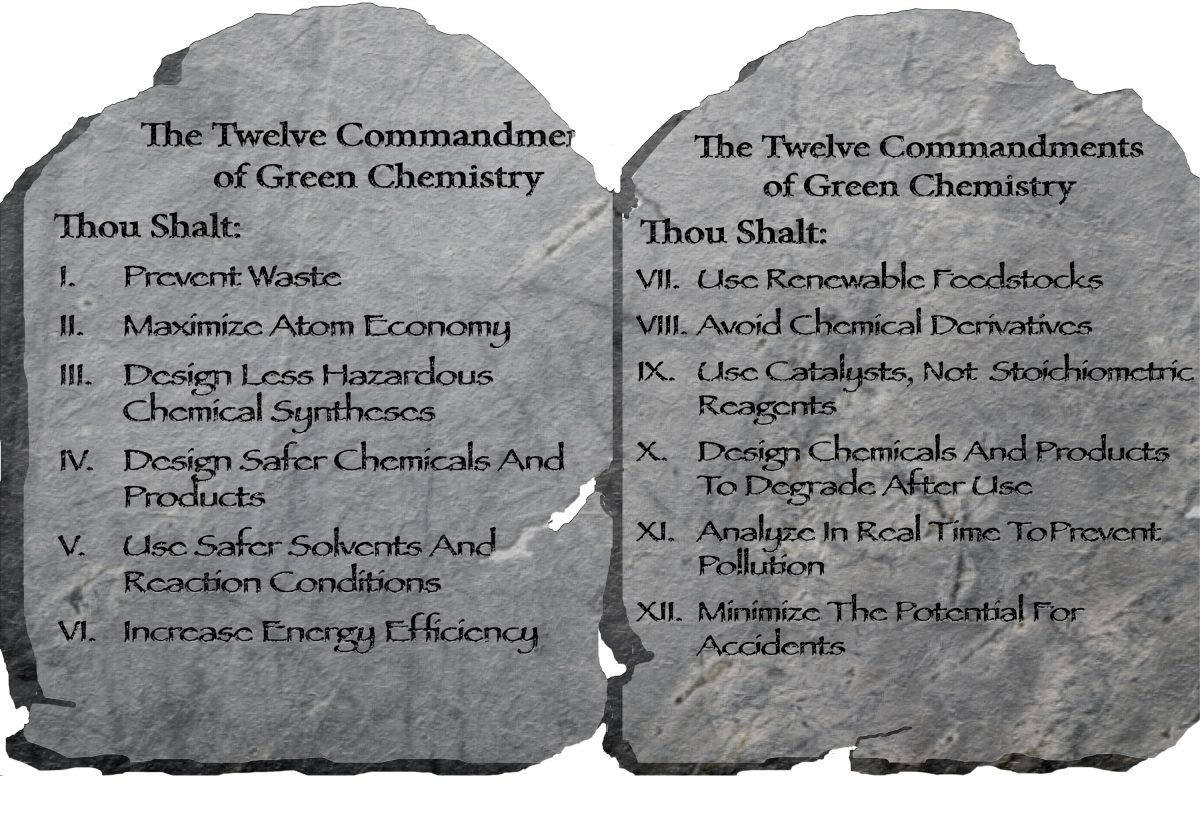

Our latest blog series is designed to guide peptide chemists towards a greener, more sustainable laboratory. Each of our blog entries (or sermons, if you will) will delve into one principle. If you missed a previous one, they can be found here.

Ninth Commandment: Catalysis – Use Catalysts, Not Stoichiometric Reagents

After a brief hiatus, the results which you can read of here and here, we are returning to the Commandments with a look at how “catalytic reagents (when selective as possible) are superior to stoichiometric reagents.”

“A Paradigm Shift”

Referencing the ACS Green Chemistry site, Roger A. Sheldon, Ph.D., Emeritus Professor of Biocatalysis and Organic Chemistry, Delft University of Technology and CEO of CLEA Technologies B.V. distills many of the green chemistry concepts to prevention and effectiveness. As he says, “prevent rather than cure,” or in plainer terms, it is easy to avoid a spill than to clean it up.1,2 In fact, this takes the first and second principles and clarifies them further. As Sheldon states, “This necessitates a paradigm shift in the concept of efficiency in organic synthesis, from one that is focused on chemical yield to one that assigns value to minimization of waste” (the first principle). Catalysis is the key when maximizing atom economy (the second principle), with the E-factor (environmental factor) concept, which Sheldon formulated. 3 (The higher the E-factor, the less green a process is and has more waste generated.)

For Industrial Quantity Production, “Indispensable”

An article noted, “Long before the definition of the principles of Green Chemistry, several industrial processes in oil refining, polymer production, and many others successfully used catalysis. Especially for industrial fuel and bulk chemical production, catalytic processes are indispensable.”4 The authors assert, “Catalysis presents a key technology to enable energy and resource efficient chemical transformations.”4 In their concluding remarks, they reiterate that catalysis is “essential.” Although catalysts are not inherently more compatible with green solvents, if the reagent is more selective, and used with a green solvent, one possible side benefit of the former is to further lower the E-factor more than it would by just utilizing the solvent alone.

Other Factors to Consider

“There are two types of catalysts: heterogeneous and homogeneous. Homogeneous catalysts are more effective to obtain expected products than heterogeneous catalysts. However, … homogeneous catalysts [have] problematic disadvantages when used for fine chemicals production in the chemical and pharmaceutical industry because of metal contamination of products.”5

Also, catalysts are not inherently more selective than their stoichiometric counterparts – it really depends on the specific reaction. They can be, but they also can perform worse. However, given equal performance and cost, a catalyst is almost always favorable because of [the] reduction in reagent amount required.

Catalytic reagents are more efficient and can be greener, but the reaction must be evaluated. Think of it as an electric screwdriver: it is generally more effective (although that must be factored in with the cost), but if the “bit” doesn’t fit properly or you are working with nails, it is not going to be the correct tool. That said, greater selectivity should be considered when considering reagents.

References

- https://www.acs.org/content/acs/en/greenchemistry/principles/12-principles-of-green-chemistry.html

- https://www.acs.org/content/acs/en/greenchemistry/principles/12-design-principles-of-green-engineering.html

- https://pubs.acs.org/doi/10.1021/acssuschemeng.7b03505

- https://pubs.rsc.org/en/content/articlelanding/2008/cc/b803584a/unauth

- https://cdn.intechopen.com/pdfs/57226.pdf