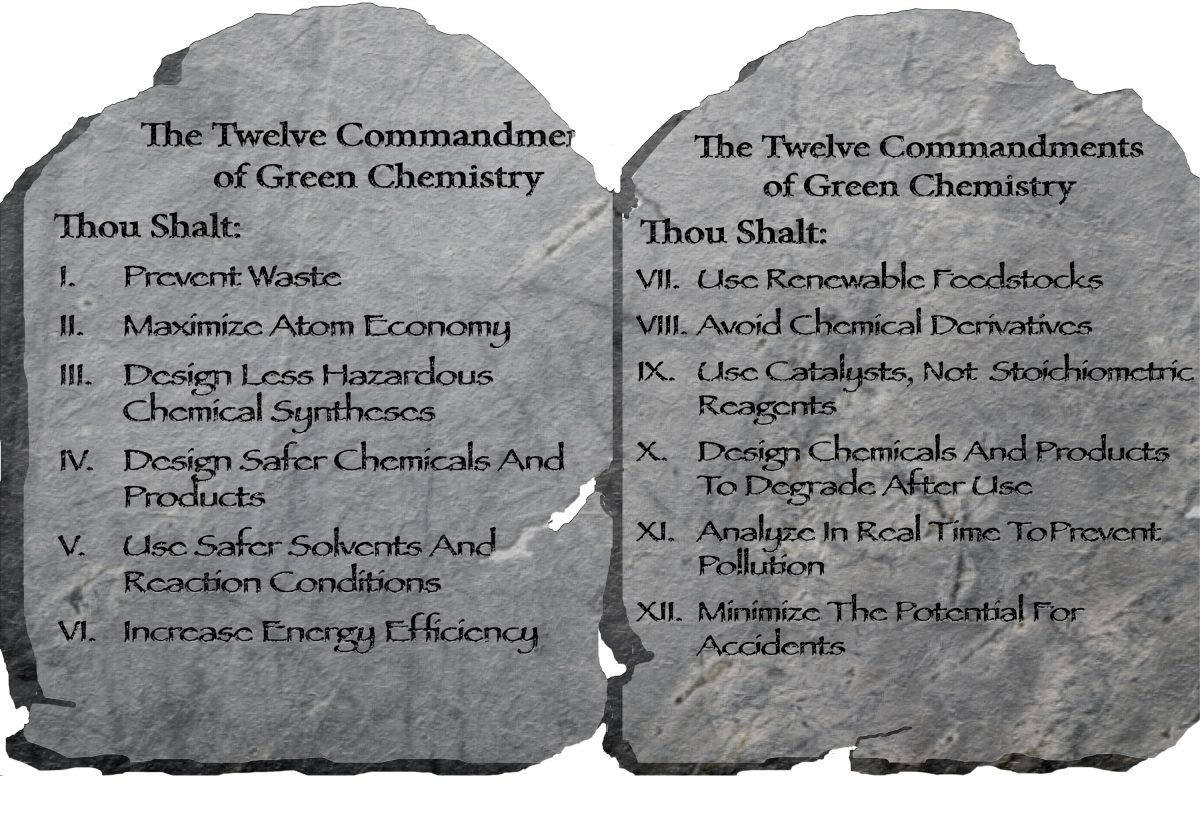

Our latest blog series guides peptide chemists towards a greener, more sustainable laboratory. Each of our blog entries (or sermons, if you will) delve into one principle. If you missed a previous one, they can be found here. In addition to the previous ten principles, we urge you to peruse our most recently published piece and its related blog here and here.

Eleventh Commandment: Real-Time Analysis for Pollution Prevention

Analytical methodologies need to be further developed to allow for real-time, in-process monitoring and control prior to the formation of hazardous substances.

As we mentioned in the previous blog, adhering to many of the twelve principles require foresight and planning, but this, our penultimate entry in this series, is one of monitoring.

The contributor to this ACS Green Chemistry post entry is Douglas Raynie, Assistant Professor, Chemistry & Biochemistry, South Dakota State University. He utilizes a metaphor of driving down a busy highway in a car with all the windows painted an opaque black to describe the need and current state of real-time analysis employed for pollution prevention.1 Fortunately, there is an organization he references, CPAC (The Center for Process Analysis & Control). This is described on their site as “a federation of member organizations for the exchange of ideas at the forefront of analytic sciences.”2 They are a cross-section of industry, national laboratories, and governmental agencies working to advance the science of analytical chemistry. While a cursory examination of the site did not reveal any returns on the search for “green chemistry,” admittedly, their research and techniques from this branch of science can be applied to this principle. By including “in-process, real-time monitoring and control during syntheses to minimize or eliminate the formation of byproducts,3” there are additional consequences besides the ability to market a process “green.”

In-process monitoring (or in-process controls) during peptide synthesis can assist in the determination of the endpoint of the reactions, adjusting for incomplete couplings, and helping with the optimization of all synthetic steps. Thus, it directly impacts the consumption of reagents, solvents, and time, thereby contributing to greener peptide chemistry. GAP peptide synthesis (GAP-PS) enables direct in-process monitoring, which can be more difficult with Solid Phase peptide synthesis (SPPS). SPPS requires an extensive sample prep process, including cleavage of the peptide from the resin, before analysis; this long sample prep time effectively destroys any semblance of real-time data feedback. In-process analysis is easy with GAP-PS, where reactions can be quickly and directly sampled for immediate injection onto standard HPLC/MS systems at any point during the synthesis process.

The added process might represent a new cost; the ability to know exactly what the toxicity of those byproducts is and minimizing or eliminating them – along with their associated expenses – are certainly worth analyzing!

References

- https://www.acs.org/content/acs/en/greenchemistry/principles/12-principles-of-green-chemistry.html

- http://cpac.apl.washington.edu/