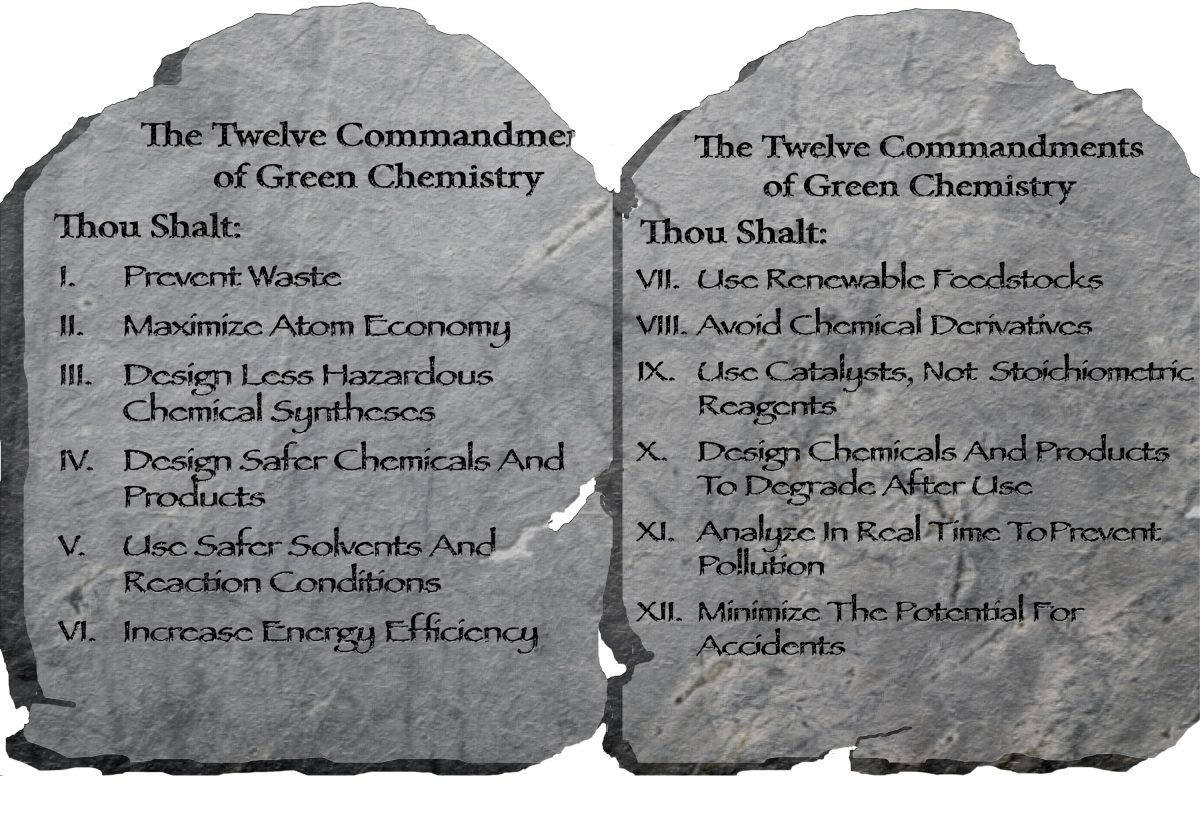

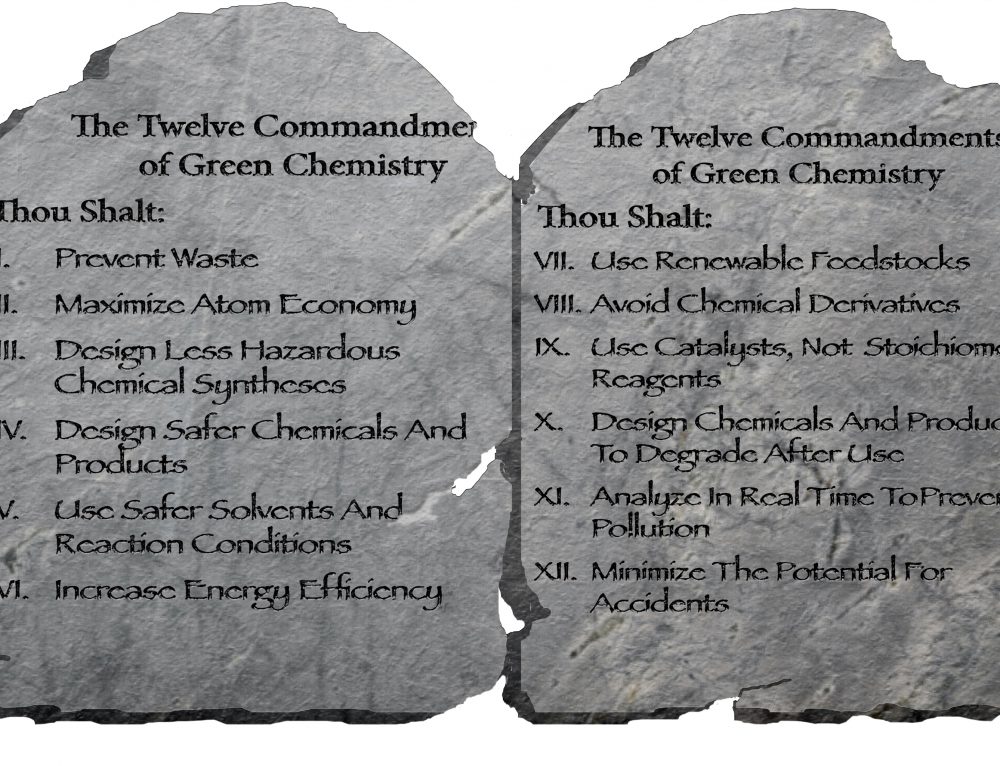

This blog series is designed to guide peptide chemists toward a greener, more sustainable laboratory. Each of our blog entries (or sermons if you will) delve into one principle. If you missed a previous one, the previous eleven principles can be found here. Additionally, we urge you to peruse our most recently published piece and its related blog here and here.

Twelfth Commandment: Inherently Safer Chemistry for Accident Prevention

Substances and the form of a substance used in a chemical process should be chosen to minimize the potential for chemical accidents, including releases, explosions, and fires.1

Our final commandment in the series is a straightforward encouragement to mitigate problems that might occur. Safety is/should/must be the paramount concern of all occupants within chemical manufacturing activities. Therefore, whenever available and feasible, less dangerous components should be utilized. Accidents invariably release or spill toxic chemicals either as a primary or secondary repercussion when they have occurred. A “primary” repercussion, refers to the dangerous chemical being the cause of the accident. A “secondary” consequence can be caused by an accident by another chemical that results in the release of a comparable or more dangerous chemical (or more likely, chemicals). For safety managers and chemical cleanup crews, this creates a worst-case possibility. It is always easier to fix one problem than multiple ones. It is even easier to prevent than fix problems. This “accident chain” is the reason that the entire spectrum of chemical safety should be moved towards greener products, lower risks, and better outcomes.

How to Start Utilizing Safer Chemicals

The U.S. Department of Labor’s Occupational Safety and Health Administration (OSHA), the main arbitrator of workplace safety in the U.S., has a helpful series of web pages that are designed as a “toolkit”.3,4 The content, while generally only advisory, is a great starting place to begin the thought and advocacy process. The site illustrates that “spectrum”, which was previously referenced, below.

In addition to making the move and substituting for ecological reasons, the site also elucidates other motivations, such as improving worker health and safety. As they state, “In the United States, it is estimated that chemicals are the cause of more than 190,000 illnesses and 50,000 deaths suffered annually by workers.”5 While those are startling numbers, the researchers believe that they are, “…likely an underestimate due to long latency periods between chemical exposures and the onset of disease, unrecognized relationships between illnesses and chemicals, and other factors. Replacing known hazardous chemicals with safer alternatives could help reduce these numbers.”5 They also present reducing costs, and the potential for regrettable substitutions, achieving compliance with laws and regulations, and creating safer products for consumers and the environment as other motivations.6

Of particular concern are chemicals that show carcinogenic, mutagenic, or reprotoxic properties (CMR for short). In accordance with the twelfth commandment, GAP-PS has eliminated CMR chemicals in its standard processes, to promote worker safety and environmental responsibility.

As we complete this final commandment, we hope this series has sparked an interest in moving towards green chemistry for peptide synthesis. The principles and guidance slightly vary in terms of complexity and difficulty, yet they all require two common traits that chemists must bring to the equation: planning and a desire to break long-established habits!

References

- https://www.acs.org/content/acs/en/greenchemistry/principles/12-principles-of-green-chemistry.html

- Anastas, P. T.; Warner, J. C.Green Chemistry: Theory and Practice; Oxford University Press; New York, 1998.

- US OSHA,OSHA releases new resources to better protect workers from hazardous chemicals, (accessed 11/22/2013)

- US OSHA,Transitioning to Safer Chemicals: A Toolkit for Employers and Workers, (accessed 11/22/2013)

- This number is derived using the methodology from “Green Chemistry in California: A Framework for Leadership in Chemicals Policy and Innovation,” (http://coeh.berkeley.edu/docs/news/06_wilson_policy.pdf *(PDF)) to estimate illness and deaths attributable to workplace chemical exposures.

- US OSHA, Why Transition to Safer Alternatives?, (accessed 11/22/2013)

- Manuele, F. A.Acceptable Risk, Professional Safety, 2010, 30-38 (accessed 11/22/2013)