This just-completed series was designed to guide peptide chemists toward a greener, more sustainable laboratory. If you want to read a previous entry, they can all be found here. Additionally, we urge you to peruse our most recently published piece and its related blog here and here.

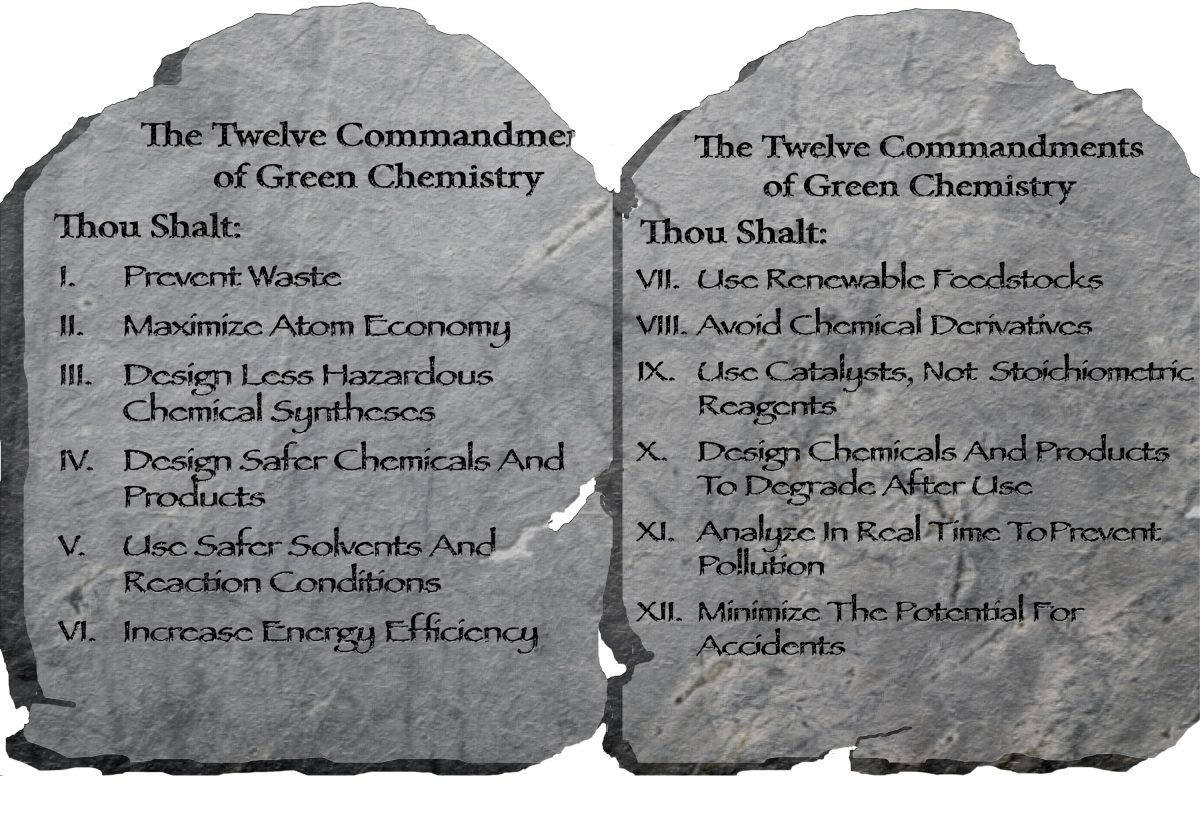

A Review of the Twelve Commandments of Green Chemistry

At the conclusion of these entries, we are reviewing the entire series to draw out two overarching themes. We are taking the opportunity to briefly address how Group Assisted Purification Peptide Synthesis (GAP-PS) practices these themes.

Design

Prevention was not only the first principle, by Berkeley W. Cue, Jr., Ph.D., of BWC Pharma Consulting, LLC, it is the principle that takes precedence over all others.1 This thematic strand of foresight and planning was also noted in our tenth entry. Going beyond usual protocols implicitly requires preparation. ‘Design’ is defined to do or plan something with a specific purpose or intention as a goal. GAP-PS was intentionally designed to prevent waste; optimize energy usage; increase synthetic efficiency through the reduction of raw materials and processing steps; and minimize solvents consumed. Since the original ideation in 2015, the inventor of GAP peptide synthesis has formulated GAP-PS to design procedures, process methods, and materials usage toward safer, more sustainable chemistry. For companies seeking to attain ESG targets, utilizing GAP-PS as a green platform technology for peptide synthesis demonstrates openness to innovation, intentionality, and preparation in the journey to improving their organization’s environmental impact.

Solvents

As we also noted in the tenth entry (Design Chemicals and Products to Degrade After Use), solvents appear multiple times in the 12 Commandments Series. This is due to solvents being one of the most hazardous components of peptide synthesis. The fifth entry, by Dr. Concepcíon (Conchita) Jiménez-González, Director, Operational Sustainability, GlaxoSmithKline, contained the following statement: “It has also been shown that solvents account for 50 – 80 percent of the mass in a standard batch chemical operation, depending on whether you include water or you don’t. Moreover, solvents account for about 75% of the cumulative life cycle environmental impacts of a standard batch chemical operation.”1 Research published shows that, on average, producing 1 kg of peptide API may require up to 15 metric tons of solvent, and waste disposal costs are billions of dollars annually. GAP-PS utilizes the green solvent 2-MeTHF, a recognized green alternative to traditional solvents used in peptide synthesis. 2-MeTHF is derived from renewable resources (waste agricultural products), is readily biodegradable, and easily recyclable.2 Solvents are also an implicit or explicit factor of principles 1,2, 3, 5, 6, 10, and 12. The “how” of design and prevention clearly points to utilizing solvent replacement as one course of action.

GAP Peptides

In addition to these two themes, GAP Peptides’ technology provides a practical, affordable, roadmap for adopting a green chemistry approach to large-scale peptide manufacturing. We offer an efficient, economical, easily scalable, and sustainable synthetic method that delivers significant manufacturing benefits: improving both operational and strategic business performance.

Our sincere hope is that, through our 12 Commandments of Green Chemistry series, we prompted curiosity for researchers to take their first steps toward green chemistry for peptide synthesis. There are numerous resources that were referenced in each blog and there are countless others to be accessed online to assist in the exploration and application of greener peptide synthesis methods.

The authors note that while gains can be made by retrofitting existing peptide manufacturing processes to adopt green chemistry principles – and increasingly, research results are promoted online to call attention to incremental progress being made – the most effective strategy is intentionally designed, innovative methods built on green chemistry design principles. GAP Peptides, LLC has been perfecting this since 2017 and we invite you to learn more about our technology at www.GAPPeptides.com.

References

- https://www.acs.org/content/acs/en/greenchemistry/principles/12-principles-of-green-chemistry.html

- https://doi.org/10.1002/cssc.201100780