5/25/2021

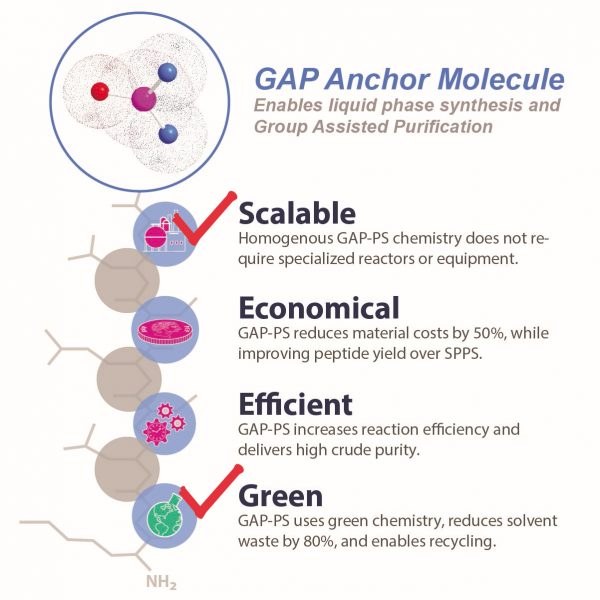

This new blog series is designed to illustrate the advantages of Group Assisted Purification Peptide Synthesis (GAP-PS) from GAP Peptides, based on the five foundational principles of our philosophy. Those principles are Scalability, Efficiency, Economy, Quality, and Green Chemistry. One of the easiest ways to do this is by highlighting peer-reviewed papers applicable to these topics. Our first entry in the series covered Green Chemistry and it can be accessed here.

Scalability is a crucial component for a viable peptide manufacturing strategy since successful peptide research has to be easily increased and consistently reproducible. Some recent articles address this topic in conjunction with green peptide synthesis.

The first is a review article, “Greening the synthesis of Peptide Therapeutics: An Industrial Perspective”, which was published late in 2020 in the journal RSC Advances, and authored by a group from Novo Nordisk, Denmark led by Vincent Martin. In it, they specifically address the very issue of scalability in green peptide synthesis. Solid-phase peptide synthesis (SPPS) has been broadly adopted due to its relative ease of automation and scalability. However, with the far-reaching environmental impact of the extensive solvent use required, alternatives are necessary. One of the most common ways to mitigate this has been focused on solvent substitution. They cite GAP Peptides’ patented liquid-phase peptide synthesis (LPPS) with group-assisted purification as one approach, with “excellent yield and purity without chromatography”.1

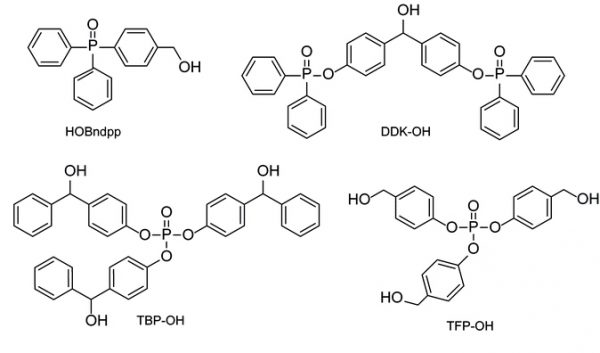

LPPS with group-assisted purification (GAP) based on much smaller phosphine oxide- or phosphate-based benzylic scaffolds have been reported. Seifert et al. developed a soluble and re-usable diphenylphosphine oxide-benzyl tag (HOBndpp) for LPPS of a pentamer in excellent yield and purity without chromatography, (See reference 1, figure 10A for more information)

Another recent – and very nice – article, this time in the publication Chimica Oggi – Chemistry Today, Dr. Michael Pennington et. al. from AmbioPharm also examines the issues and promise found in green chemistry, including scalability. They also reference GAP Peptides founder Dr. Cole Seifert’s technology as being a strong option as well.2

As a dynamic and pioneering company, GAP Peptides has espoused these synergies with the approach they advocate, since its inception. Our embrace of Green Chemistry, combined with our patented Group Assisted Purification Peptide Synthesis (GAP-PS), allows chemists to deliver peptides with fewer resources, greater safety, and less hazardous waste than traditional methods. We invite you to investigate our contract research service, which in addition to those advantages, also offers all this at a substantially lower cost than traditional synthesis methods. Sustainability with less expensive synthesis – what’s holding you back? Contact GAP Peptides for more information today!

References

- Vincent Martin , Peter H. G. Egelund , Henrik Johansson , Sebastian Thordal Le Quement , Felix Wojcik and Daniel Sejer Pedersen, RSC Adv., 10, 42457 (2020). (Review Article) DOI: 10.1039/D0RA07204D

- Michael W. Pennington, Denise Karounos, Chris J. Bai, Chimica Oggi – Chemistry Today, 39(2), 56 (2021). (PDF)

Further Reading

- Vincent Martin, Sandip Jadhav, Peter H. G. Egelund, Raphael Liffert, Henrik Johansson Castro, Tobias Krüger, Kim F. Haselmann, Sebastian Thordal Le Quement, Fernando Albericio, Frank Dettner, Carolin Lechner,Ralph Schönleber, and Daniel Sejer Pedersen, Green Chem., 23, 3295 (2021). DOI: 10.1039/D1GC00603G

- Michael W. Pennington, Brant Zell, Chris J. Bai, Medicine in Drug Discovery, 9, 100071 (2021). DOI: 10.1016/j.medidd.2020.100071